ASTM A182 / A182M UNS K31390

ASTM A182 UNS K31390 is a forging material specification for 20% Nickel, 8% Chromium alloy steel and is used for manufacturing bare forgings or forged and machined products for applications involving high temperature service. Ferrobend offers forged flanges, fittings, valves bodies, fasteners, plates, bars, rings and similar pressure parts in ASTM A182 UNS k31390 specification.

ASTM A182 specification covers requirements such as chemical composition, mechanical properties, heat treatment and other supplementary requirements for 1 stainless steel forgings and forged products.

Chemical Composition

| Grade Symbol | UNS Number | Alloy | Elements | Composition % |

|---|---|---|---|---|

| F3VCb | K31390 |

3% chromium, 1% molybdenum, 0.25% vanadium plus boron, columbium, and titanium |

Carbon | 0.10–0.15 |

| Manganese | 0.30 - 0.60 | |||

| Phosphorus | 0.020 max | |||

| Sulfur | 0.010 max | |||

| Silicon | 0.10 max | |||

| Nickel | 0.25 max | |||

| Chromium | 2.7 - 3.3 | |||

| Molybdenum | 0.90 - 1.10 | |||

| Columbium | 0.015–0.070 | |||

| Titanium | 0.015 max | |||

| Vanadium | 0.20 - 0.30 | |||

| Copper | 0.25 max | |||

| Calcium | 0.0005 - 0.0150 |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength, min, ksi [MPa] | 85-110 [585-760] |

| Yield Strength, min, ksi [MPa] | 60 [415] |

| Elongation in 2 in. [50mm] or 4D, min, % | 18 |

| Reduction or Area, min, % | 45 |

| Brinell Hardness Number, HBW | 174-237 |

Products

-

Flanges

Sizes : 1/8" to 96"

Pressure Rating : Upto 2500 lbs

Types : Weld Neck, Slip-on, Blind, Threaded, etc.

-

Fittings

Sizes : 1/8" to 48"

Ends : Bevelled, SocketWeld, Threaded and Flanged.

Types : Buttweld, Socketweld, Threaded, Block type, etc.

-

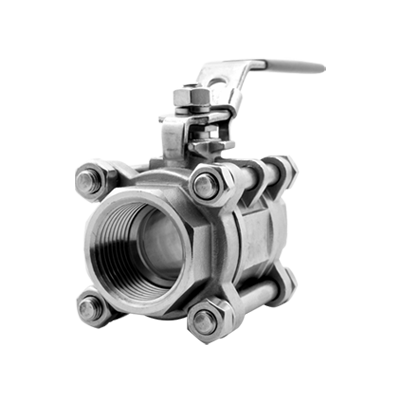

Valves

Sizes : 1/8" to 96"

End Connection : Buttweld, Flanged, Threaded, etc.

Types : Butterfly, Ball, Gate, Globe, Pinch, etc.

-

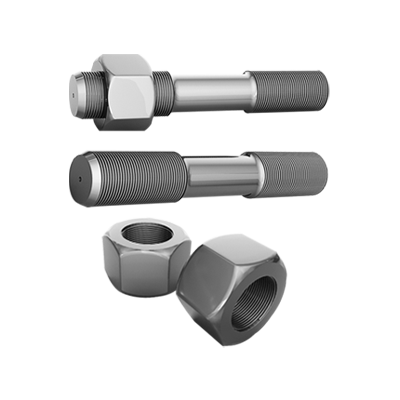

Fasteners

Sizes : 1/8" to 8" / M3 to M180

Dimensions : DIN / ISO / UNI / ASME and Customized.

Types : Hex Bolts, Stud Bolts, Socket Head Cap Screws, Hex Nuts, Flat Washers, etc.

-

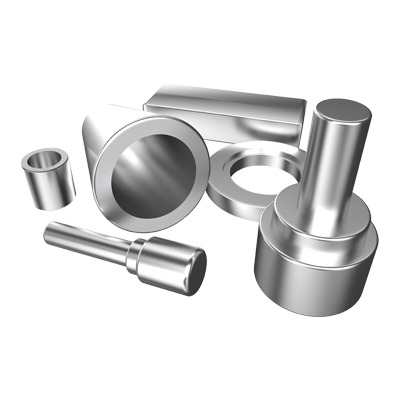

Forgings

Size : 50mm to 3000mm

Weight capacity : 30gms to 5000 kgs

Types : Fittings, Flanges, Valves, Rings, Bars, Components, etc.

-

Plates

-

Bars & Rods

-

Rings