ASTM A765 / A765M

This specification2 covers heat-treated carbon steel and alloy steel forgings with mandatory toughness requirements.These forgings are intended for pressure vessels, feedwater heaters, and similar uses.These forgings include tube sheets, covers, channel barrels, integral forged channels, rings, nozzles, flanges, and similar parts.All grades are considered weldable under proper conditions.The maximum thickness of forgings produced to this specification is limited only by the capacity of the selected grade to respond to any heat treatment specified and to meet the specified mechanical tests, including impact tests at the specified temperature.Material supplied to this specification shall conform to the requirements of Specification A 788/A 788M, which outlines additional ordering information, manufacturing requirements,testing and retesting methods and procedures, marking,certification, product analysis variations, and additional supplementary requirements.If the requirements of this specification are in conflict with the requirements of Specification A 788/A 788M, the requirements of this specification shall prevail.

Grade

| Grade | Description |

|---|---|

| I | - |

| II | - |

| III | - |

| IV | - |

| V | - |

Chemical Properties

| Grade | Carbon, max | Manganese | Phosphorus, | Sulfur, max | Silicon, max | Chromium,A max | Nickel, maxA | Molybdenum,A max | Vanadium, max | Aluminum, max | Copper, max |

|---|---|---|---|---|---|---|---|---|---|---|---|

| I | 0.30 | 0.60 to 1.35 |

0.020 | 0.020 | 0.15 to 0.35 |

0.40 | 0.50 | 0.10 | 0.05 | 0.05 | 0.35 |

| II | 0.30 | 0.60 to 1.35 |

0.020 | 0.020 | 0.15 to 0.35 |

0.40 | 0.50 | 0.10 | 0.05 | 0.05 | 0.35 |

| III | 0.20 | 0.90 max | 0.020 | 0.020 | 0.15 to 0.35 |

0.20 | 3.3 to 3.8 | 0.06 | 0.05 | 0.05 | 0.35 |

| IV | 0.20 | 1.00–1.60 | 0.020 | 0.020 | 0.15–0.50 | 0.40 | 0.50 max | 0.10 | 0.06 | 0.05 | 0.35 |

| V | 0.30 | 0.60–1.35 | 0.020 | 0.020 | 0.15–0.35 | 0.30 | 1.0–2.0 | 0.12 | 0.03 | 0.05 | 0.35 |

Note: A Intentional additions of Cr, Mo, and Ni up to the specified maximum are permitted to be made to Grades I, II, and IV by the manufacturer.

Mechanical Properties

| Class | Tensile strength, ksi [MPa] | Yield strengthA min, ksi [MPa] |

Elongation in 2 in. or 50 mm, min, % |

Reduction of area, min, % | |

|---|---|---|---|---|---|

| I | 60 to 85 [415 to 585] |

30 [205] | 25 | 38 | |

| II | 70 to 95 [485 to 655] |

36 [250] | 22 | 30 | |

| III | 70 to 95 [485 to 655] |

37.5 [260] | 22 | 35 | |

| IV | 80–105 [550–725] |

50 [345] | 22 | 30 | |

| V | Class 1 | 60–85 [415– 585] |

30 [205] | 25 | 38 |

| Class 2 | 70–95 [485–655] |

37.5 [260] | 22 | 35 | |

Note: A0.2 % offset or 0.5 % total extension underload method.

Products

-

Forged Bars

Sizes :

Length :

Finish :

-

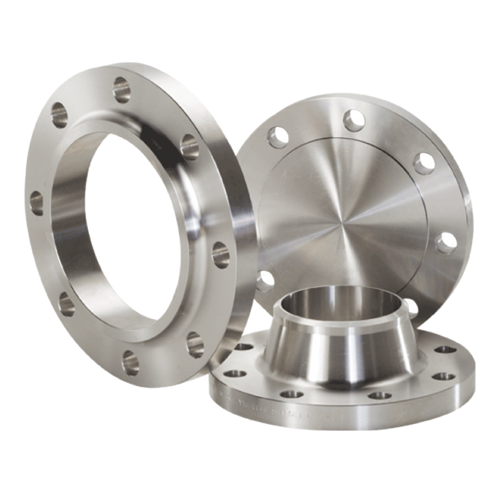

Forged Flanges

Sizes :

Length :

Finish :

-

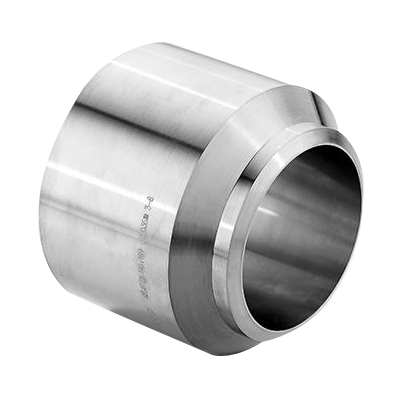

Forged Fittings

Sizes :

Length :

Finish :

-

Forged Valves

Sizes :

Length :

Finish :

-

Forged Blank

Sizes :

Length :

Finish :

-

Forged Disc

Sizes :

Length :

Finish :

-

Forged Pipe

Sizes :

Length :

Finish :

-

Forged Component

Sizes :

Length :

Finish :