ASTM A707 / A707M

This specification covers forged carbon and alloy steel flanges

intended primarily for petroleum and gas pipelines in areas subject

to low ambient temperatures. Included are flanges to specified

dimensions or to dimensional standards such as those MSS, ASME, and

API specifications that are referenced in Section 2. Supplementary

requirements are provided for use when additional requirements are

desired. These shall apply only when specified individually by the

purchaser in the order. Eight grades, four yield-strength classes,

and three different notch toughness levels are included. The

availability of a particular size of flange of a specific grade and

class is limited only by the capability of the composition to meet

the specified mechanical property requirements. However, current

practice normally limits the following:

(a) Grade L1 to Classes 1 and 2,

(b) Grade L2 to Classes 1, 2, and 3,

(c) Grade L3 to Classes 1, 2, and 3,

(d) Grade L4 to Classes 1, 2, and 3,

(e) Grade L7 to Classes 1 and 2, and

(f) Grades L5, L6, and L8 are generally available in any class.

This specification is expressed in both inch-pound units and in SI

units. However, unless the order specifies the applicable “M”

specification designation (SI units), the material shall be

furnished to inch-pound units.

Grade

| Grade | Description |

|---|---|

| L1 | - |

| L2 | - |

| L3 | - |

| L4 | - |

| L5 | - |

| L6 | - |

| L7 | - |

| L8 | - |

Chemical Properties

| Grade | Carbon, max, % | Manganese,% | Phosphorus, max, % | Sulfur, max, % | Silicon, max, % | Chromium,% | Nickel,% | Molybdenum,% | Vanadium,% | Nitrogen,% | Copper,% | Columbium, % |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L1 | 0.23 | 0.55 - 1.60 | 0.035 | 0.040 | 0.37 | 0.34 max | 0.43 max | 0.13 max | 0.06 max | ... | 0.43 max | 0.03 max |

| L2 | 0.33 | 0.55 - 1.45 | 0.035 | 0.040 | 0.37 | 0.34 max | 0.43 max | 0.13 max | 0.06 max | ... | 0.43 max | 0.03 max |

| L3 | 0.25 | 1.05 - 1.60 | 0.030 | 0.035 | 0.32 | 0.34 max | 0.43 max | 0.13 max | 0.03 – 0.13 | 0.005–0.035 | 0.18 minC | 0.03 max |

| L4 | 0.20 | 0.40 - 0.70 | 0.030 | 0.035 | 0.37 | 0.34 max | 1.60 – 2.05 | 0.19 – 0.33 | 0.06 max | ... | 0.43 max | 0.03 max |

| L5 | 0.09 | 0.35 – 0.75 | 0.030 | 0.035 | 0.37 | 0.56–0.94 | 0.67 – 1.03 | 0.14 – 0.28 | 0.06 max | ... | 0.95–1.35 | 0.02 min |

| L6 | 0.09 | 1.75 – 2.30 | 0.030 | 0.035 | 0.17 | 0.34 max | 0.43 max | 0.22 – 0.38 | 0.06 max | ... | 0.43 max | 0.05–0.11 |

| L7 | 0.22 | 1.00 max | 0.030 | 0.035 | 0.37 | 0.34 max | 3.18 – 3.82 | 0.13 max | 0.06 max | ... | 0.43 max | 0.03 max |

| L8 | 0.22 | 0.15 – 0.45 | 0.025 | 0.025 | 0.37 | 1.44 – 2.06 | 2.68 – 3.97 | 0.35 – 0.65 | 0.06 max | ... | 0.43 max | 0.03 max |

Note : C When specified.

Mechanical Properties

| Class | Yield strengthA min, ksi [MPa] | Tensile strength, min, ksi [MPa] |

Elongation in 2 in. or 50 mm, min, % |

Reduction of area, min, % | Hardness, HBW |

Cv energy absorption,B,C min, avg, ft·lbf [J] |

Cv energy absorption,B,D min, ft·lbf [J] |

|---|---|---|---|---|---|---|---|

| Class 1 |

42 [290] |

60 [415] |

22 | 40 | 149–207 | 30 [41] | 24 [33] |

| Class 2 |

52 [360] |

66 [455] |

22 | 40 | 149–217 | 40 [54] | 32 [43] |

| Class 3 |

60 [415] |

75 [515] |

20 | 40 | 156–235 | 50 [68] | 40 [54] |

| Class 4 |

75 [515] |

90 [620] |

20 | 40 | 179–265 | 50 [68] | 40 [54] |

Products

-

Forged Bars

Sizes :

Length :

Finish :

-

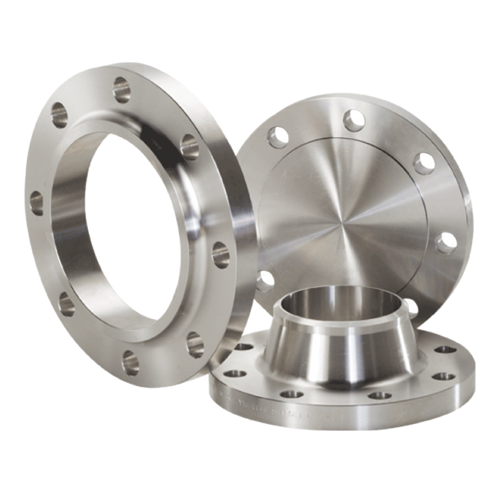

Forged Flanges

Sizes :

Length :

Finish :

-

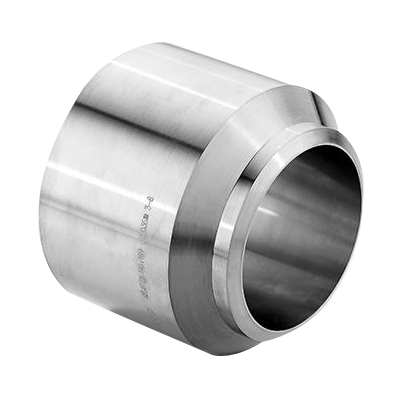

Forged Fittings

Sizes :

Length :

Finish :

-

Forged Valves

Sizes :

Length :

Finish :

-

Forged Blank

Sizes :

Length :

Finish :

-

Forged Disc

Sizes :

Length :

Finish :

-

Forged Pipe

Sizes :

Length :

Finish :

-

Forged Component

Sizes :

Length :

Finish :