ASTM A369 / A369M

This specification2 covers heavy-wall carbon and alloy steel pipe made from turned and bored forgings and is intended for high-temperature service. Pipe ordered under this specification shall be suitable for bending and other forming operations and for fusion welding. Selection will depend on design, service conditions, mechanical properties and hightemperature characteristics. NOTE 1—The use of the word “pipe” throughout the several sections of this specification is used in the broad sense and intended to mean pipe headers, or leads. NOTE 2—The dimensionless designator NPS (nominal pipe size) has been substituted in this standard for such traditional terms as “nominal diameter,” “size,” and “nominal size.” Several grades of ferritic steels are covered. Supplementary requirements (S1 to S6) of an optional nature are provided. These supplementary requirements call for additional tests to be made, and when desired shall be so stated in the order, together with the number of such tests required.

Chemical Properties

| Grade | Carbon | Manganese | Phosphorus | Sulphur | Silicon | Chromium | Molybdenum | Others |

|---|---|---|---|---|---|---|---|---|

| FPA | 0.25 max | 0.27 – 0.93 | 0.035 max | 0.035 max | 0.10 min | ... | ... | ... |

| FPB | 0.30 max | 0.29 – 1.06 | 0.035 max | 0.035 max | 0.10 min | ... | ... | ... |

| FP1 | 0.10 - 0.20 | 0.30 – 0.80 | 0.025 max | 0.025 max | 0.10 - 0.50 | ... | 0.44 - 0.65 | ... |

| FP5 | 0.15 max | 0.30 – 0.60 | 0.025 | 0.025 | 0.50 max | 4.00 - 6.00 | 0.45 - 0.65 | ... |

| FP9 | 0.15 max | 0.30 – 0.60 | 0.030 | 0.030 | 0.50 - 1.00 | 8.00 - 10.00 | 0.90 - 1.10 | ... |

| FP11 | 0.05 - 0.15 | 0.30 – 0.60 | 0.025 | 0.025 | 0.50 - 1.00 | 1.00 - 1.50 | 0.44 - 0.65 | ... |

| FP21 | 0.05 - 0.15 | 0.30 – 0.60 | 0.025 | 0.025 | 0.50 max | 2.65 - 3.35 | 0.80 - 1.06 | ... |

| FP22 | 0.05 - 0.15 | 0.30 – 0.60 | 0.025 | 0.025 | 0.50 max | 1.90 - 2.60 | 0.87 - 1.13 | ... |

| FP91 | 0.06 - 0.12 | 0.30 – 0.60 | 0.025 | 0.025 | 0.20 - 0.50 | 8.00 - 9.50 | 0.85 - 1.05 |

Ni 0.40 max V 0.18–0.25 Cb 0.06–0.10 N 0.03–0.07 Al 0.02 max Ti 0.01 max Zr 0.01 max |

| FP92 | 0.07 - 0.13 | 0.30 – 0.60 | 0.020 | 0.010 | 0.50 max | 8.50 - 9.50 | 0.30 - 0.60 |

W 1.50–2.00 V 0.15–0.25 Cb 0.04–0.09 N 0.030–0.070 Ni 0.40 max Al 0.02 max Ti 0.01 max Zr 0.01 max B 0.001–0.006 |

Mechanical Properties

| Grade | Tensile Strength, ksi [MPa] | Yield Strength, ksi [MPa] |

|---|---|---|

| FPA | 48 [330] | 30 [210] |

| FPB | 60 [415] | 35 [240] |

| FP1,FP2 | 55 [380] | 30 [210] |

| FP12 | 60 [415] | 32 [220] |

| FP91 | 85 [585] | 60 [415] |

| FP92 | 90 [620] | 64 [440] |

| All Others | 60 [415] | 30 [210] |

Products

-

Forged Bars

Sizes :

Length :

Finish :

-

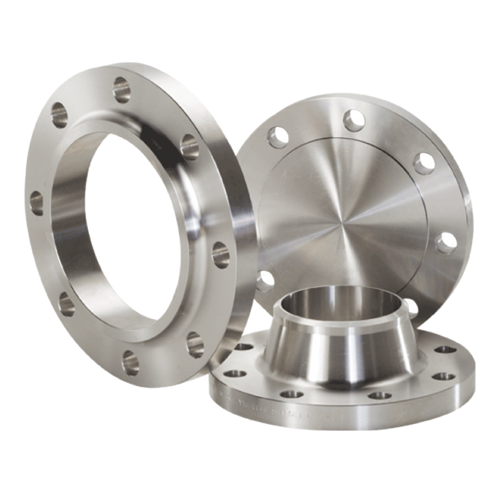

Forged Flanges

Sizes :

Length :

Finish :

-

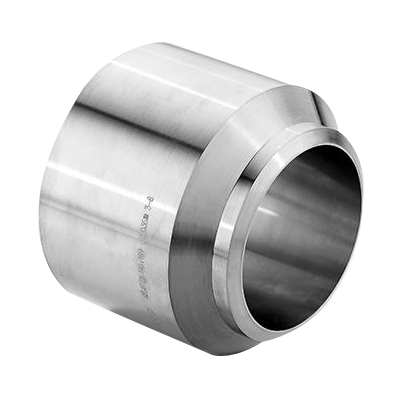

Forged Fittings

Sizes :

Length :

Finish :

-

Forged Valves

Sizes :

Length :

Finish :

-

Forged Blank

Sizes :

Length :

Finish :

-

Forged Disc

Sizes :

Length :

Finish :

-

Forged Pipe

Sizes :

Length :

Finish :

-

Forged Component

Sizes :

Length :

Finish :