ASTM A1049 / A1049M

This specification covers ferritic/austenitic (duplex) stainless steel forgings for boilers, pressure vessels, and associated equipment in grades that are also found in Specification A 182/A 182M.The purchaser may specify in the order or contract any appropriate supplementary requirements that are provided in Specification A 788/A 788M. Unless the order specifies the applicable “M” specification designation the material shall be furnished to the inchpound units.

Grade

| UNS Designation |

Grade |

|---|---|

| S31200 | F50 |

| S31803 | F51 |

| S32950 | F52 |

| S32750 | F53 |

| S39274 | F54 |

| S32760 | F55 |

| S39277 | F57 |

| S32520 | F59 |

| S32205 | F60 |

| S32550 | F61 |

Note: A Water quenching is required unless the use of another liquid quenching medium is approved by the purchaser

Chemical Properties

| Grade | Carbon, max | Manganese, max | Phosphorus, max | Sulfur, max | Silicon, max | Nickel | Chromium | Molybdenum | Nitrogen | Copper | Tungsten |

|---|---|---|---|---|---|---|---|---|---|---|---|

| S31200 | 0.030 | 2.00 | 0.045 | 0.030 | 1.00 | 5.5-6.5 | 24.0-26.0 | 1.20-2.00 | 0.14-0.20 | . . . | . . . |

| S31803 | 0.030 | 2.00 | 0.030 | 0.020 | 1.00 | 4.5-6.5 | 21.0-23.0 | 2.5-3.5 | 0.08-0.20 | . . . | . . . |

| S32950 | 0.030 | 2.00 | 0.035 | 0.010 | 0.60 | 3.5-5.2 | 26.0-29.0 | 1.00-2.50 | 0.15-0.35 | . . . | . . . |

| S32750 | 0.030 | 1.20 | 0.035 | 0.020 | 0.80 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 | 0.24-0.32 | 0.50 max | . . . |

| S39274 | 0.030 | 1.00 | 0.030 | 0.020 | 0.80 | 6.0-8.0 | 24.0-26.0 | 2.5-3.5 | 0.24-0.32 | 0.20-0.80 | 1.50-2.50 |

| S32760 | 0.030 | 1.00 | 0.030 | 0.010 | 1.00 | 6.0-8.0 | 24.0-26.0 | 3.0-4.0 | 0.20-0.30 | 0.50-1.00 | 0.50-1.00 |

| S39277 | 0.025 | 0.80 | 0.025 | 0.002 | 0.80 | 6.5-8.0 | 24.0-26.0 | 3.0-4.0 | 0.23-0.33 | 1.20-2.00 | 0.80-1.20 |

| S32520 | 0.030 | 1.50 | 0.035 | 0.020 | 0.80 | 5.5-8.0 | 24.0-26.0 | 3.0-5.0 | 0.20-0.35 | 0.50-3.00 | . . . |

| S32205 | 0.030 | 2.00 | 0.030 | 0.020 | 1.00 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 | 0.14-0.20 | . . . | . . . |

| S32550 | 0.04 | 1.50 | 0.040 | 0.030 | 1.00 | 4.5-6.5 | 24.0-27.0 | 2.9-3.9 | 0.10-0.25 | 1.50-2.50 | . . . |

Note :

A PREN = Cr + 3.3(Mo) + 16(N)

B PREN = Cr + 3.3(Mo + 1⁄2 W) + 16(N)

Mechanical Properties

| UNS Designation |

Grade | Tensile Strength ksi [MPa] Minimum or Range |

Yield Strength 0.2 % Offset ksi [MPa] Minimum |

Elongation % in 2 in. or 50 mm Minimum |

Reduction of Area % Minimum |

Brinell Hardness HB Maximum |

|---|---|---|---|---|---|---|

| S31200 | F50 | 100-130 [690-900] | 65 [450] | 25 | 50 | . . . |

| S31803 | F51 | 90 [620] | 65 [450] | 25 | 45 | . . . |

| S32950 | F52 | 100 [690] | 70 [485] | 15 | 45 | . . . |

| S32750 | F53 | 116 [800] | 80 [550] | 15 | 45 | 310 |

| S39274 | F54 | 116 [800] | 80 [550] | 15 | 30 | 310 |

| S32760 | F55 | 109-130 [750-900] | 80 [550] | 25 | 45 | . . . |

| S39277 | F57 | 118 [815] | 85 [585] | 25 | 50 | . . . |

| S32520 | F59 | 112 [770] | 80 [550] | 25 | 40 | . . . |

| S32205 | F60 | 95 [655] | 70 [485] | 25 | 45 | . . . |

| S32550 | F61 | 109 [750] | 80 [550] | 25 | 50 | . . . |

Products

-

Forged Bars

Sizes :

Length :

Finish :

-

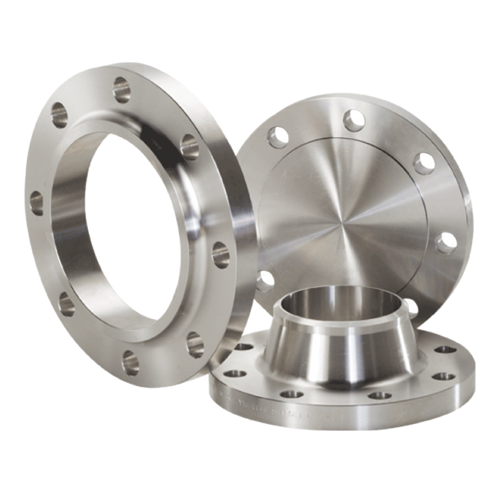

Forged Flanges

Sizes :

Length :

Finish :

-

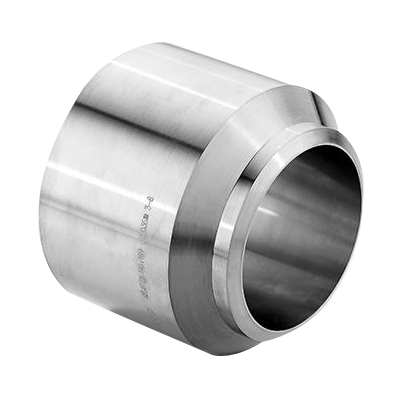

Forged Fittings

Sizes :

Length :

Finish :

-

Forged Valves

Sizes :

Length :

Finish :

-

Forged Blank

Sizes :

Length :

Finish :

-

Forged Disc

Sizes :

Length :

Finish :

-

Forged Pipe

Sizes :

Length :

Finish :

-

Forged Component

Sizes :

Length :

Finish :