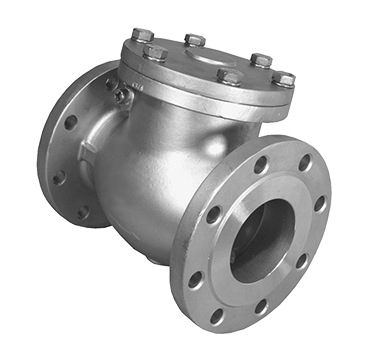

AISI 904L Check Valves

AISI 904L Check Valves are one way non return valves installed in a pipeline to protect the process or equipment from reverse flow. Common types includes swing check valve, dual disc type check valve, wafer type check valve, ball check valve, tilting disc check valve and piston check valves. 904L check valves have flanged end to bolt with other flanges or just sandwiched between flanges.

Anand Steels is a manufacturer and supplier of AISI 904L checks valves with bolted flanged ends. AISI 904L valves are manufactured to ANSI/ASME B16.34, API 602 and BS 5351 standards. 904L ball valves and valves parts are constructed with ASTM A182/A182M F904L, A276/A276M type 904L and A479/A479M UNS N08904 material specifications. Stainless steel 904l valves are duly marked for traceability. We offer worldwide shipping by Sea or Air freight options.

For more information on AISI 904L Check Valves, see below details.

- Sizes: 3/8” to 24” NPS

- Sub Types: swing check valve, dual disc type check valve, wafer type check valve, ball check valve, tilting disc check valve and piston check valves

- Pressure Ratings: Class 75/150/300/400/600/900/1500/2500 and others

- Connections: Flanged

- Construction: Cast body, forged and fabricated.

- Standards: ANSI/ASME B16.34, B16.10, API 594, MSS-SP-71, MSS-SP-61, BS 5153, BS 5352, BS 1868, API 6D, API 602.

- Material Specifications: ASTM / ASME A182 F904L, Cast 904L / UNS N08904, Uranus® B6, X1-Ni-Cr-Mo-Cu-25-20-5, DIN/EN/Werkstoff Number 1.4539

- Origin: India, China, Taiwan, Korea, Japan, Sweden, Italy, France, Germany, UK & USA

Chemical Requirements for AISI 904L Check Valves

| Elements | Composition, % |

|---|---|

| Carbon (C) | 0.02 Max |

| Manganese (Mn) | 2.00 Max |

| Phosphorus (P) | 0.04 Max |

| Sulfur (S) | 0.03 Max |

| Silicon (Si) | 1.00 Max |

| Chromium (Cr) | 19.00 – 23.00 Max |

| Nickel (Ni) | 23.00 – 28.00 Max |

| Molybdenum | 4.00 – 5.00 Max |

| Copper (Cu) | 1.00 – 2.00 Max |

| Nitrogen (N) | 0.10 Max |

Mechanical Requirements for AISI 904L Check Valves

| Elements | Composition | |

|---|---|---|

| Tensile Strength, min ksi [MPa] | 71 [490] | |

| Yield Strength, min ksi [MPa] | 31 [215] | |

| Elongation in 2 inch or 50mm (or 4D), min % | Longitudinal | 35 |

| Transverse | 25 | |

Applications for AISI 904L Check Valves

- Process equipment in chemical industry

- Petrochemical industry

- Bleaching equipment in the pulp and paper industry

- Flue gas cleaning

- Desalination

- Seawater handling

- Hydrometallurgy

- Food and beverage

- Pharmaceuticals

- Heat exchangers