AISI 904L Forged Valves

AISI 904L Forged Valves have greater strength as compared to cast body valves and have high pressure retaining capacity. 904L forged valve bodies are costlier but sustainable with longer service life. This includes ball valves, globe, gate valves, check valves, needle valves, etc.

Anand Steels is a manufacturer and supplier of AISI 904L forged valves with flanged end, socket-weld, threaded and butt-weld connections. Available in variety of types, sizes and pressure class, these 904L forged valves are produced in full compliance with ASTM A182/A182M F904L material specifications. Stainless steel 904l forged valves are duly marked for traceability. We offer worldwide shipping by Sea or Air freight options.

For more information on AISI 904L Forged Valves, see below details.

- Sizes: 1/2” to 24”

- End Connections: Flanged end, socket-weld, screwed and Butt-weld.

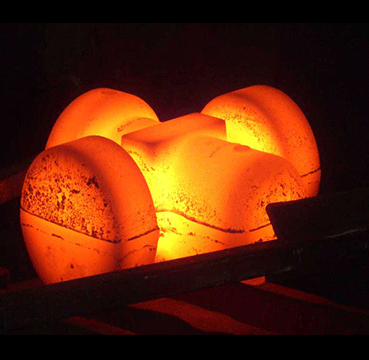

- Construction: Hot Forged

- Design Standards: BS 5351 / API 602 / ASME B16.34

- Testing Standards: API 598 / BS 6755 Part II

- Face to Face Dimensions: ANSI / ASME B16.10

- Other Standards: ANSI/ASME B16.9, B16.11, B16.5, B16.47 Series A & B, ASME B1.20.1, B16.25

- Material Specifications: ASTM / ASME A182 F904L, Type 904L / UNS N08904, Uranus® B6, X1-Ni-Cr-Mo-Cu-25-20-5, DIN/EN/Werkstoff Number 1.4539

- Origin: India, China, Taiwan, Korea, Japan, Sweden, Italy, France, Germany, UK & USA

Chemical Requirements for AISI 904L Forged Valves

| Elements | Composition, % |

|---|---|

| Carbon (C) | 0.02 Max |

| Manganese (Mn) | 2.00 Max |

| Phosphorus (P) | 0.04 Max |

| Sulfur (S) | 0.03 Max |

| Silicon (Si) | 1.00 Max |

| Chromium (Cr) | 19.00 – 23.00 Max |

| Nickel (Ni) | 23.00 – 28.00 Max |

| Molybdenum | 4.00 – 5.00 Max |

| Copper (Cu) | 1.00 – 2.00 Max |

| Nitrogen (N) | 0.10 Max |

Mechanical Requirements for AISI 904L Forged Valves

| Elements | Composition | |

|---|---|---|

| Tensile Strength, min ksi [MPa] | 71 [490] | |

| Yield Strength, min ksi [MPa] | 31 [215] | |

| Elongation in 2 inch or 50mm (or 4D), min % | Longitudinal | 35 |

| Transverse | 25 | |

Applications for AISI 904L Forged Valves

- Process equipment in chemical industry

- Petrochemical industry

- Bleaching equipment in the pulp and paper industry

- Flue gas cleaning

- Desalination

- Seawater handling

- Hydrometallurgy

- Food and beverage

- Pharmaceuticals

- Heat exchangers