AISI 904L Forged Fittings

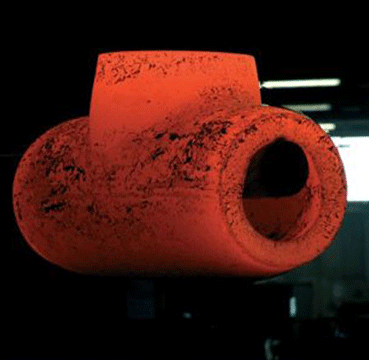

AISI 904L Forged Fittings covers a range of high strength pipe fittings with fine grain structure, suitable for high temperature or high pressure piping applications. This includes forged socket-weld, threaded fittings classified under ANSI/ASME B16.11 and block type buttweld fittings under ANSI/ASME B16.9.

Anand Steels is a manufacturer and supplier of AISI 904L forged fittings in variety of sizes and pressure class. 904L forged fittings are produced in full compliance with ASTM A182/A182M F904L material specifications. Stainless steel 904l forged fittings are duly marked for traceability. We offer worldwide shipping by Sea or Air freight options.

For more information on AISI 904L Forged Fittings, see below details.

- Sizes: 1/2” to 4” with socket-weld and screwed ends. Up to 24” in butt-weld ends.

- Forgings Weight: from 100 grams to 3000 Kilograms.

- Construction: Hot Forging

- Dimensions & Tolerances;: ASME / ANSI , BS, EN, ISO, GOST and DIN Standards

- Material Specifications: ASTM / ASME A182 F904L, Type 904L / UNS N08904, Uranus® B6, X1-Ni-Cr-Mo-Cu-25-20-5, DIN/EN/Werkstoff Number 1.4539

- Origin: India, China, Taiwan, Korea, Japan, Sweden, Italy, France, Germany, UK & USA

Chemical Requirements for AISI 904L Forged Fittings

| Elements | Composition, % |

|---|---|

| Carbon (C) | 0.02 Max |

| Manganese (Mn) | 2.00 Max |

| Phosphorus (P) | 0.04 Max |

| Sulfur (S) | 0.03 Max |

| Silicon (Si) | 1.00 Max |

| Chromium (Cr) | 19.00 – 23.00 Max |

| Nickel (Ni) | 23.00 – 28.00 Max |

| Molybdenum | 4.00 – 5.00 Max |

| Copper (Cu) | 1.00 – 2.00 Max |

| Nitrogen (N) | 0.10 Max |

Mechanical Requirements for AISI 904L Forged Fittings

| Elements | Composition | |

|---|---|---|

| Tensile Strength, min ksi [MPa] | 71 [490] | |

| Yield Strength, min ksi [MPa] | 31 [215] | |

| Elongation in 2 inch or 50mm (or 4D), min % | Longitudinal | 35 |

| Transverse | 25 | |

Applications for AISI 904L Forged Fittings

- Process equipment in chemical industry

- Petrochemical industry

- Bleaching equipment in the pulp and paper industry

- Flue gas cleaning

- Desalination

- Seawater handling

- Hydrometallurgy

- Food and beverage

- Pharmaceuticals

- Heat exchangers