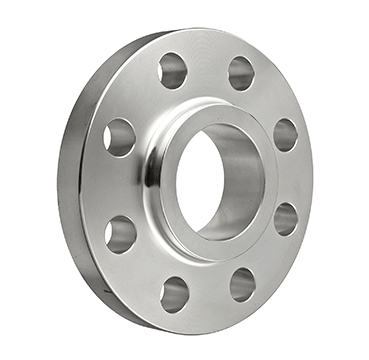

AISI 904L Slip On Flanges

AISI 904L Slip-on Flanges are used to connect pipes, fittings, valves, strainers and other components within a pipeline. Anand Steels is a manufacturer, stockist and supplier of stainless steel 904l slip-on flanges with flat face and raised face configuration.

AISI 904L Slip-on flanges are manufactured to ASTM A182/A182M F904L forged material specification and ANSI/ASME B16.5, BS 1560, EN 1092-1, ISO, GOST and various DIN standards. AISI 904L Slip-on flanges can also be machined from plates to ASTM A240/A240M Type 904L (UNS N08904) material specification. AISI 904L slip-on pipe flanges are duly marked for traceability. We offer worldwide shipping by Sea or Air freight options.

For more information on AISI 904L Slip On Flanges, see below details.

- Sizes: 3/8” to 24” NPS

- Pressure Ratings: Class 75/150/300/400/600/900/1500/2500; PN6, PN10, PN16, PN25 & PN40.

- Facing: Flat Face & Raised Face

- Construction: Hot Forged and Plate Machined

- Dimensions & Tolerances;: ASME / ANSI , BS, EN, ISO, GOST and DIN Standards

- Material Specifications: ASTM / ASME A182 F904L, ASTM A240/A240M Type 904L / UNS N08904, Uranus® B6, X1-Ni-Cr-Mo-Cu-25-20-5, DIN/EN/Werkstoff Number 1.4539

- Origin: India, China, Taiwan, Korea, Japan, Sweden, Italy, France, Germany, UK & USA

Chemical Requirements for AISI 904L Slip On Flanges

| Elements | Composition, % |

|---|---|

| Carbon (C) | 0.02 Max |

| Manganese (Mn) | 2.00 Max |

| Phosphorus (P) | 0.04 Max |

| Sulfur (S) | 0.03 Max |

| Silicon (Si) | 1.00 Max |

| Chromium (Cr) | 19.00 – 23.00 Max |

| Nickel (Ni) | 23.00 – 28.00 Max |

| Molybdenum | 4.00 – 5.00 Max |

| Copper (Cu) | 1.00 – 2.00 Max |

| Nitrogen (N) | 0.10 Max |

Mechanical Requirements for AISI 904L Slip On Flanges

| Elements | Composition | |

|---|---|---|

| Tensile Strength, min ksi [MPa] | 71 [490] | |

| Yield Strength, min ksi [MPa] | 31 [215] | |

| Elongation in 2 inch or 50mm (or 4D), min % | Longitudinal | 35 |

| Transverse | 25 | |

Applications for AISI 904L Slip On Flanges

- Process equipment in chemical industry

- Petrochemical industry

- Bleaching equipment in the pulp and paper industry

- Flue gas cleaning

- Desalination

- Seawater handling

- Hydrometallurgy

- Food and beverage

- Pharmaceuticals

- Heat exchangers