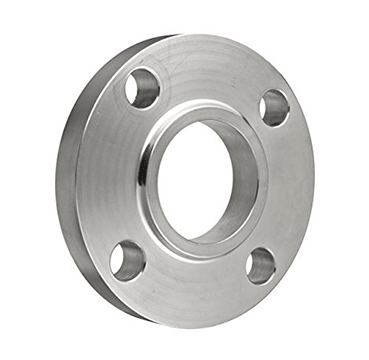

AISI 904L Lap Joint Flanges

AISI 904L Lap Joint Flanges are flat face ring type flange, used in union with a serrated stub end, not directly in touch with flowing medium. Designed to cheaper the cost of the piping, 904L lap joint flanges could be used with higher alloyed stub end such nickel, Inconel or Hastelloy alloys.

Anand Steels is a manufacturer, stockist and supplier of AISI 904L lap joint flanges. These 904l lap joint flanges are usually machined from plates to ASTM A240/A240M Type 904L / UNS N08904 material specification or could be conventionally hot forged and machined to ASTM A182/A182M F904L material specifications. 904L Lapped flanges are manufactured to suit ANSI/ASME B16.5 or DIN dimensional standards. AISI 904L pipe flanges are duly marked for traceability. We offer worldwide shipping by Sea or Air freight options.

For more information on AISI 904L Lap Joint Flanges, see below details.

- Sizes: ½’ to 24” NPS

- Pressure Ratings: Class 75/150/300/400/600/900/1500/2500; PN6 and PN10.

- Construction: Forged and Plate Machined

- Dimensions & Tolerances;: ASME / ANSI , BS, EN, ISO, GOST and DIN Standards

- Material Specifications: ASTM / ASME A182 F904L, ASTM A240/A240M Type 904L / UNS N08904, Uranus® B6, X1-Ni-Cr-Mo-Cu-25-20-5, DIN/EN/Werkstoff Number 1.4539

- Origin: India, China, Taiwan, Korea, Japan, Sweden, Italy, France, Germany, UK & USA

Chemical Requirements for AISI 904L Lap Joint Flanges

| Elements | Composition, % |

|---|---|

| Carbon (C) | 0.02 Max |

| Manganese (Mn) | 2.00 Max |

| Phosphorus (P) | 0.04 Max |

| Sulfur (S) | 0.03 Max |

| Silicon (Si) | 1.00 Max |

| Chromium (Cr) | 19.00 – 23.00 Max |

| Nickel (Ni) | 23.00 – 28.00 Max |

| Molybdenum | 4.00 – 5.00 Max |

| Copper (Cu) | 1.00 – 2.00 Max |

| Nitrogen (N) | 0.10 Max |

Mechanical Requirements for AISI 904L Lap Joint Flanges

| Elements | Composition | |

|---|---|---|

| Tensile Strength, min ksi [MPa] | 71 [490] | |

| Yield Strength, min ksi [MPa] | 31 [215] | |

| Elongation in 2 inch or 50mm (or 4D), min % | Longitudinal | 35 |

| Transverse | 25 | |

Applications for AISI 904L Lap Joint Flanges

- Process equipment in chemical industry

- Petrochemical industry

- Bleaching equipment in the pulp and paper industry

- Flue gas cleaning

- Desalination

- Seawater handling

- Hydrometallurgy

- Food and beverage

- Pharmaceuticals

- Heat exchangers