AISI 904L Castings

AISI 904L Forgings includes fittings, flanges, valve bodies, seamless rings, bars and blocks for use in high pressure or high temperature applications. These AISI 904L forged parts have finer grain structure and high integrity in containing high pressure that are suitable for wide range of services

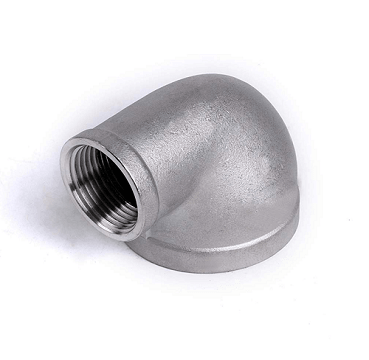

Anand Steels manufactures and supplies AISI 904L castings in form of fittings, flanges, valves, fasteners, plates and other complex parts which are difficult and costlier to produce using conventional process. AISI 904L castings have no defined specification under ASTM / ASME standards. AISI 904L castings are duly marked for traceability. We offer worldwide shipping by Sea or Air freight options.

AISI 904L Castings Categories

For more information on AISI 904L Castings, see below details.

- Sizes: 25mm to 3000mm in Diameter

- Forging Weight: 50gm up to 3000 Kilograms.

- Allied Products: Fittings, Flanges, Valves, Strainers, Fasteners, Plates, Blocks, Custom Parts

- Construction: Sand Casting, Die Casting, Investment Casting, etc.

- Material Specifications: Type 904L / UNS N08904, Uranus® B6, X1-Ni-Cr-Mo-Cu-25-20-5, DIN/EN/Werkstoff Number 1.4539

- Origin: India, China, Taiwan, Korea, Japan, Sweden, Italy, France, Germany, UK & USA

Chemical Requirements for AISI 904L Castings

| Elements | Composition, % |

|---|---|

| Carbon (C) | 0.02 Max |

| Manganese (Mn) | 2.00 Max |

| Phosphorus (P) | 0.04 Max |

| Sulfur (S) | 0.03 Max |

| Silicon (Si) | 1.00 Max |

| Chromium (Cr) | 19.00 – 23.00 Max |

| Nickel (Ni) | 23.00 – 28.00 Max |

| Molybdenum | 4.00 – 5.00 Max |

| Copper (Cu) | 1.00 – 2.00 Max |

| Nitrogen (N) | 0.10 Max |

Mechanical Requirements for AISI 904L Castings

| Elements | Composition | |

|---|---|---|

| Tensile Strength, min ksi [MPa] | 71 [490] | |

| Yield Strength, min ksi [MPa] | 31 [215] | |

| Elongation in 2 inch or 50mm (or 4D), min % | Longitudinal | 35 |

| Transverse | 25 | |

Applications for AISI 904L Castings

- Process equipment in chemical industry

- Petrochemical industry

- Bleaching equipment in the pulp and paper industry

- Flue gas cleaning

- Desalination

- Seawater handling

- Hydrometallurgy

- Food and beverage

- Pharmaceuticals

- Heat exchangers