AISI 904L

AISI 904L is a low carbon, non-stabilized austenitic type stainless steel alloy. With addition of copper, AISI 904L has improved resistance to strong reducing acids such as sulphuric acid. With high level of molybdenum provides 904L with superior resistance to pitting and crevice corrosion. Due to its high alloying, 904L is also quite resistant to stress corrosion cracking. As compared to 300 series stainless steel type, grade 904l stainless steel is superior. AISI 904L is also non-magnetic, offers excellent toughness, formability and weldability.

AISI 904L Chemical Composition

| Elements | Composition, % |

|---|---|

| Carbon (C) | 0.02 Max |

| Manganese (Mn) | 2.00 Max |

| Phosphorus (P) | 0.045 Max |

| Sulfur (S) | 0.035 Max |

| Silicon (Si) | 1.00 Max |

| Chromium (Cr) | 19.00 – 23.00 Max |

| Nickel (Ni) | 23.00 – 28.00 Max |

| Molybdenum | 4.00 – 5.00 Max |

| Copper (Cu) | 1.00 – 2.00 Max |

| Nitrogen (N) | 0.10 Max |

AISI 904L Mechanical Properties

| Property | Composition | |

|---|---|---|

| &emsb; Tensile Strength, min ksi [MPa] | 71 [490] | |

| Yield Strength, min ksi [MPa] | 31 [220] | |

| Elongation in 2 inch or 50mm (or 4D), min % | Longitudinal | 35 |

AISI 904L Physical Properties

| Elastic Modulus | 190 GPa |

| Mean Co-Efficient of Expansion (0-100ºC) | 15 µm/m/ºC |

| Thermal Conductivity (At 20ºC) | 11.5 W/m.K |

| Specific Heat (0-100ºC) | 500 J/Kg.K |

| Electric Resistivity | 952 nΩ.m |

| Density | 7900 Kg/m3 or 493 Lb/ft3 |

| Melting Point | 1300 – 1390 ºC (2372 – 2534º F) |

AISI 904L Heat Treatment

904L has austenitic stainless steel chemistry and can be strengthened by solution annealing at 1090 to 1175ºC, followed by rapid water quenching. 904L can be hardened using heat treatment.

AISI 904L Machining

AISI 904L can be machined using any standard methods. It can be readily bent to a small radius under cold conditions. Although subsequent annealing is not required in most cases, it should be carried out when the fabrication is performed under severe stress corrosion cracking (SCC) conditions.

AISI 904L Equivalent Grades & Designation

| SAE / AISI | 904L |

| UNS | N08904 |

| DIN / EN / Werkstoff Number | 1.4539 |

| EURO NORM / DIN NAME | X1-Ni-Cr-Mo-CU-25-20-2 |

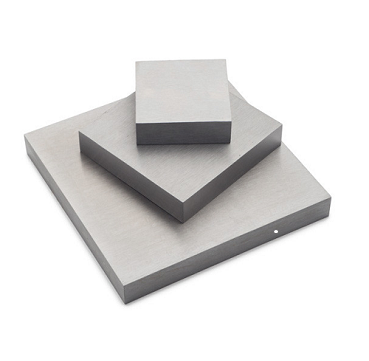

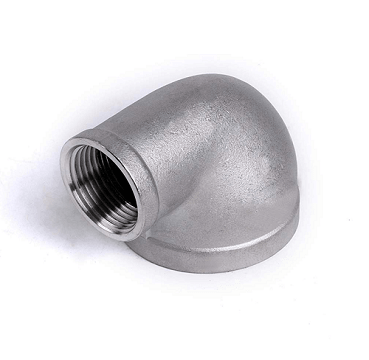

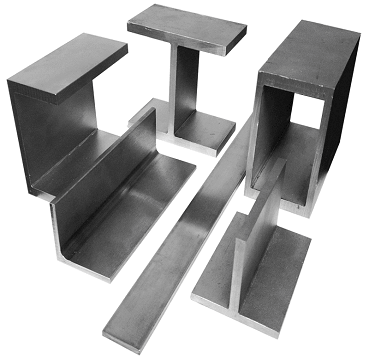

AISI 904L Products Specifications

| Seamless / Welded Pipes | ASTM A312 / ASME SA312 UNS N08904 |

| Seamless / Welded Tubes | ASTM A269 / ASME SA269 UNS N08904 |

| Bars / Rods | ASTM A276 / A479 UNS N08904 |

| Forgings | ASTM A182 F904L |

| Sheets / Plates / Strips | ASTM A240 UNS N08904 / ASME SA240 UNS N08904 |

| Welding Consumables | AWS A5.9 ER385 |

904L Alternative Grade

| SS 316L | With Lower corrosion resistance and cost effective |

| 6 Mo Alloys | With higher resistance to pitting and crevice corrosion |

| Duplex 2205 | With similar corrosion resistance, higher mechanical strength and lower cost but not suitable for temperature above 300ºC |

AISI 904L Applications

- Chemical processing units involving phosphoric, sulphuric and acetic acids

- Oil and gas platforms

- Pharmaceutical Industry